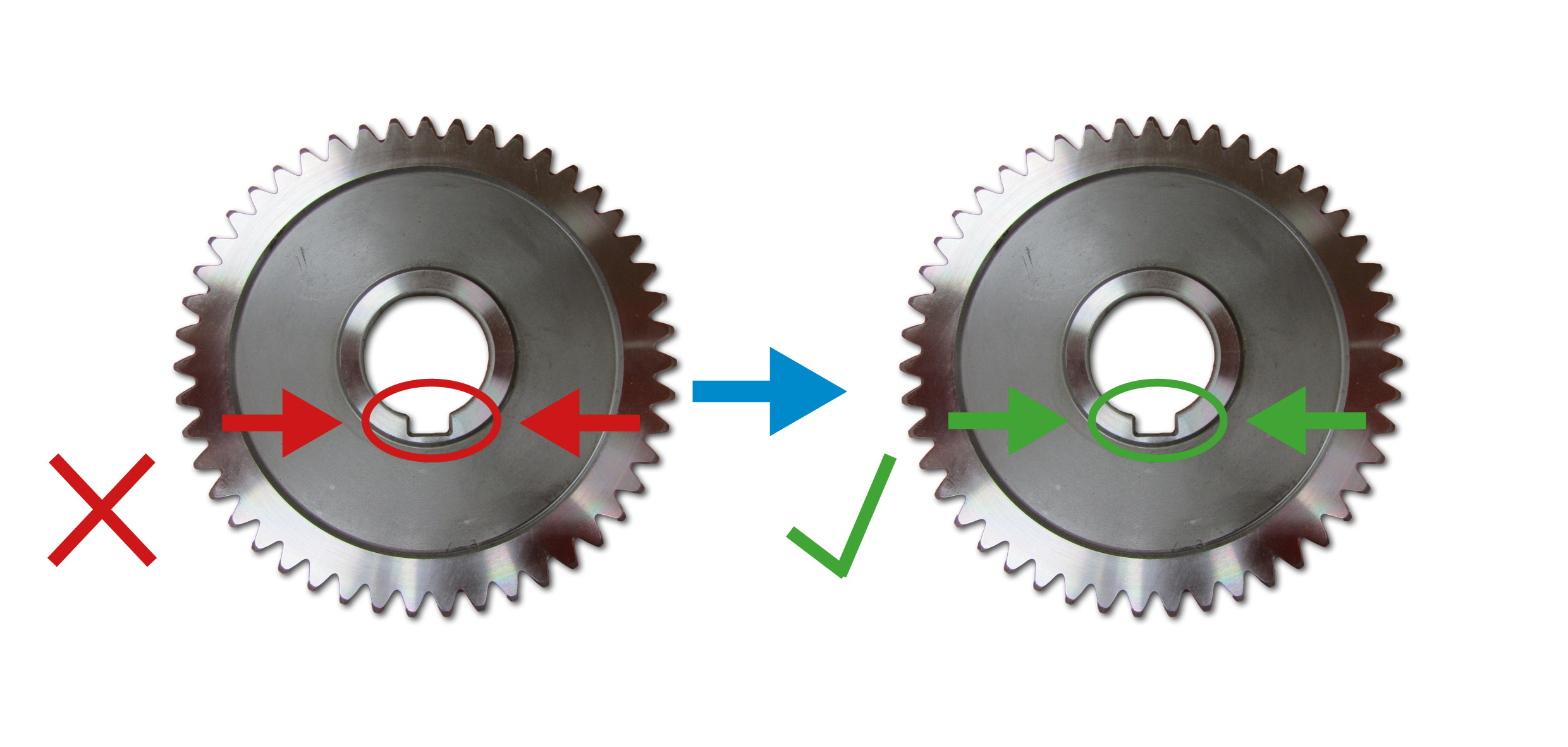

Hardening deviations on keyways

We have the solution: RE-KE – Tool

The invention relates to a method for reworking grooved internal profiles especially keyways in hardened wheels. In the manufacture of hardened pieces with keyways the problem keeps arising that individual parts of the pieces are not dimensionally stable after the hardening process and must be reworked. This reworking is usually made by additional grinding operations. These operations are increasing the production costs considerably. The service life of these tools is relatively short, especially for larger deviations a reworking is often not possible. Due to these unsatisfactory methods and tools, Rehfuss has developped a method and tools for finishing grooved inner profiles after hardening process. Hardening deviations can be removed simply, quickly and economically. This reworking can be booked as Service in the REhfuss premisses or can be carried out on your own after signing a License Agreement. The tool used has been developped especially and is Utility model protected.